Thermally

Conductive KC TM substrates is the best

state-of-the-art solution for transferring excess heat from electronic

devices to a heat sink. Various elastic

substrates are efficient for low power

applications. In all other cases, it is strongly recommended to use ceramics.

KC TM

substrates are based on aluminum oxide (Al2O3), which

greatly surpasses elastic materials (such as mica silicates, etc) in thermal conductivity and provides the best

performance for electronic devices, regardless of their power.

KC TM

substrates made from aluminum nitride (AlN) are noted for their outstanding thermal conductivity,

comparable to the conductivity of beryllium oxide-based ceramics, which are

potentially carcinogenic. They are not

only cheaper and safer than modern beryllium ceramics, but also exceed

their price / quality ratio.

Table

of comparative materials

|

|

Substrate Material / thickness |

Thermal

conductivity (W/m*K) |

Thermal

resistance (K/W) |

Improved efficiency/ratio |

|

|

Mica 0,05

mm |

0,7 |

0,170 |

1,4 |

||

|

Nomakon 0,2 mm |

2 |

0,240 |

1 |

||

|

KC TM

Ceramics |

Al2O3 |

Al2O3 0,25 mm |

25 |

0,03 |

8,6 |

|

Al2O3 0,4

mm |

25 |

0,040 |

5 |

||

|

Al2O3 0,63 mm |

25 |

0,060 |

3,3 |

||

|

Al2O3 1,0

mm |

25 |

0,100 |

2 |

||

|

AlN |

AlN 0,25mm |

180 |

0,004 |

60 |

|

|

AlN 0,5 mm |

180 |

0,007 |

30 |

||

|

AlN 1,0 mm |

180 |

0,014 |

15 |

||

|

AlN 2,0 mm |

180 |

0,028 |

7,5 |

||

Aluminum Oxide (Al2O3) substrate

with T=0,25 mm exceeds thermal

conductivity scale of elastic substrate by almost 10 times; that of mica silicate –

by 6 times.

KC TM

substrates have much better finishing

surface than in stamped substrates

and can be produced

in thickness range up to 0.25 mm.

There exists a concern among engineers

regarding the fragility of ceramic substrates. However, KC TM

ceramic

substrates of 0.25 mm and thinner are

able to bend slightly, and are not very sensitive to possible unevenness in

heat sink surfaces to which they are to be applied. KC TM

substrates can withstand any reasonable pressure - they can be broken, but

not crushed!

The high thermal conductivity of KC

TM substrates enables their use at greater thickness without critical

deterioration of thermal resistance. This can reduce stray capacitance between

the device and the heat sink, which is critical in devices such as

low-frequency power amplifiers. 1-mm thick aluminum nitride based KC TM substrate

reduces stray capacitance by 20 times

and has 10 times lower minimal thermal resistance compared to an

analogous mica substrate.

The

guaranteed dielectric strength of

KC TM substrates is at least 16 kV / mm for AlN and over 20kV/mm

for Al2O3, which is almost two twice higher than in machine-stamped ceramic

substrates.

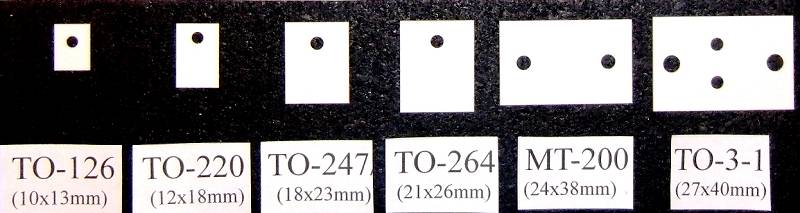

Aluminum Nitride substrates:

Aluminum Oxide substrates:

Gratify your appliances with KC TM ceramics and solve

the question of "thermal

conductivity + Quality vs. Price" once and

for all!